In the virtual age, supply chains have developed from simply logistical frameworks to becoming strategic assets for agencies. The shift from conventional to virtual delivery chains has revolutionized corporations’ performance, supplying them with equipment and technologies that enhance performance, transparency, and resilience. This transformation, driven by technological improvements and marketplace demands, has made virtual supply chains a critical part of contemporary enterprise.

The Rise of Digital Supply Chains

The rise of digital supply chains has revolutionized modern business, leveraging technology to enhance efficiency, transparency, and responsiveness in managing logistics and operations.

Historical Context and Early Developments

The adventure toward virtual delivery chains began with the slow automation of manual procedures. Initially, businesses relied heavily on paper statistics, manual tracking, and easy verbal exchange techniques. These conventional supply chains were regularly slow, at risk of errors, and needed more actual-time visibility. The first huge shift occurred with the creation of the net and early ERP systems, which helped centralize statistics and streamline operations.

Key Technologies and Innovations

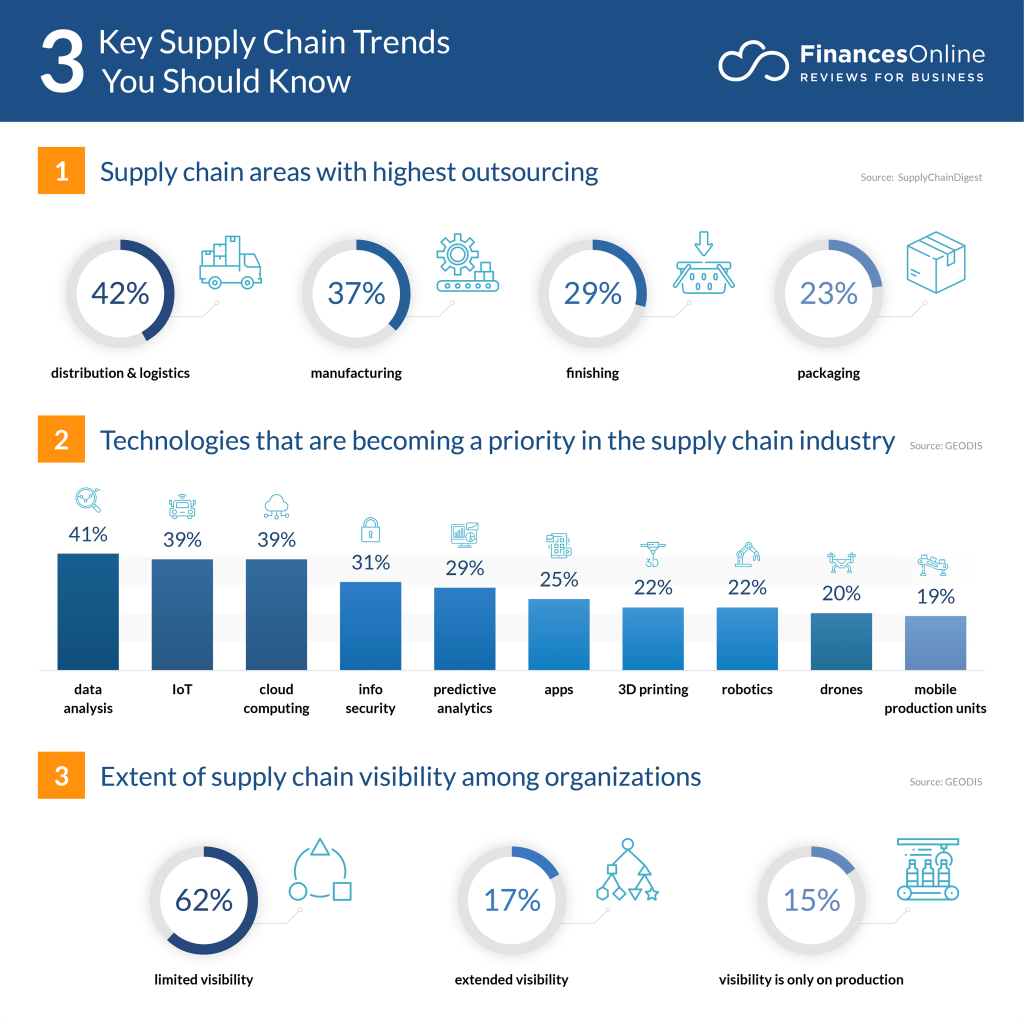

Digital technology honestly took off with the appearance of advanced technology, including the Internet of Things (IoT), synthetic intelligence (AI), and blockchain. IoT gadgets revolutionized how businesses use music and control their property, supplying real-time information on the region, condition, and movement of products. AI and machine mastering algorithms enabled predictive analytics, optimizing everything from stock management to transportation routes. The blockchain era delivered new security and transparency, making records tamper-proof and fostering agreement among supply chain partners.

Benefits of Digital Supply Chains

Digital supply chains offer significant benefits, including enhanced efficiency, real-time data insights, cost reduction, and improved risk management, making businesses more resilient and competitive.

Enhanced Efficiency and Cost Reduction

One of the biggest advantages of virtual delivery chains is the tremendous development in operational efficiency. Automation reduces the want for manual intervention, cutting down on human mistakes and dashing up techniques. For instance, computerized stock management systems can be expected. In contrast, stock stages are low, and resources are reordered routinely, ensuring that companies are not caught off protection by using stockouts.

Real-Time Data and Analytics

The potential to access real-time statistics is a game-changer for cutting-edge delivery chains. Companies can monitor each issue in their operations, from manufacturing schedules to shipping timelines, in real-time. This visibility allows for more knowledgeable choice-making and quicker responses to any disruptions. Furthermore, advanced analytics provide deep insights into patron behavior and market trends, permitting companies to tailor their strategies and stay ahead of competitors.

Improved Risk Management and Resilience

Digital supply chains enhance an agency’s ability to manage risks and build resilience. Traditional delivery chains are vulnerable to disruptions, from natural disasters to political instability. Digital systems, with their real-time tracking and predictive abilities, enable organizations to assume ability troubles and increase contingency plans. This proactive technique helps mitigate risks and ensures operations continuity, even in unexpected, demanding situations.

Challenges and Considerations

Challenges in digital supply chains include high initial investment costs, cybersecurity risks, data privacy concerns, and the need for workforce adaptation and training to new technologies.

Implementation Barriers

Despite the clear blessings, transitioning to digital delivery chains presents several demanding situations. One of the number one barriers is the sizeable preliminary investment required. Implementing virtual technology entails the value of the latest structures and software and the prices related to upgrading infrastructure and education personnel. Those costs can be especially daunting for SMEs, potentially hindering their ability to compete with large establishments.

Security and Data Privacy Concerns

As delivery chains become increasingly virtual, they become extra liable to cyberattacks. The reliance on facts and interconnected structures makes supply chains attractive goals for cybercriminals. Ensuring the security of sensitive information is paramount, requiring considerable funding for cybersecurity measures. Additionally, organizations must navigate complex data privacy guidelines and the GDPR to ensure compliance and keep purchasers in agreement.

Workforce Adaptation and Training

The digital transformation of supply chains also necessitates a shift within the team of workers. As new technology is included, there’s a growing demand for employees with virtual abilities. This need for upskilling may be challenging, especially in industries where the personnel is accustomed to conventional methods. Companies need to put money into education applications to assist their personnel in adapting and thriving in virtual environments.

Future Trends and Predictions

Future trends in digital supply chains include the expansion of AI and machine learning, increased use of autonomous vehicles, and a focus on sustainability and ethical sourcing in global logistics.

Continued Advancements in Technology

Looking to destiny, the function of AI and machines getting to know delivery chains is about to make bigger similarly. This technology will allow extra state-of-the-art predictive analytics, permitting companies to assume demand appropriately, optimize stock levels, and beautify customer support. Additionally, using drones and autonomous vehicles in logistics could revolutionize shipping structures, making them faster and more green.

The Impact of Globalization

Globalization will continue to form the evolution of virtual supply chains. As organizations expand their operations globally, the need for included, pass-border delivery chain solutions will develop. Digital delivery chains can facilitate better coordination and compliance with international policies, ensuring businesses can operate easily in several markets. Integrating blockchain technology will be vital in imparting transparency and traceability in worldwide change.

Sustainability and Ethical Considerations

Sustainability is turning into an increasingly crucial consideration in supply chain control. Consumers and stakeholders are stressed more environmentally pleasant and ethically sourced products. Digital supply chains can help businesses meet these demands by optimizing logistics to lessen carbon footprints, ensuring ethical sourcing, and improving standard sustainability. Businesses prioritizing these aspects in their delivery chains will likely benefit from an aggressive facet and build more potent purchaser loyalty.

Conclusion

Digital delivery chains have moved from an insignificant fashion to a crucial detail of present-day commercial enterprise. The integration of contemporary technologies has converted conventional delivery chain models, presenting improved efficiency, real-time facts, and threat control. While demanding situations consisting of high initial fees, safety worries, and the need for skilled personnel continue to exist, the advantages of digital delivery chains are undeniable. As the era continues to boost and globalization hurries up, embracing digital supply chains can be essential for agencies aiming to live aggressively and thrive in the international marketplace. The destiny of delivery chain management is digital, and businesses ought to adapt to this new fact to ensure their long-term fulfillment.